What Is the ANSI Z87.1 for Safety Glasses?

Do you wear safety glasses at work or during certain activities? If not, you may need a pair to protect your eyes from hazards.

That said, not all safety glasses are created equal, and that’s where safety glass ratings come into play.

In this article, we’ll focus on the ANSI standard for safety glasses, which is one of the most widely recognized safety glass ratings in the United States.

We’ll cover what it is, why it matters, and what you should look for when choosing safety glasses that meet the ANSI standard.

What is ANSI Z87.1?

The ANSI standard for safety glasses, also known as ANSI Z87.1, was established in 1968 by the American National Standards Institute.

This standard was created to ensure that safety glasses provide adequate protection against workplace hazards such as flying debris, chemicals, and radiation.

Over the years, the ANSI standard has been updated and revised to keep up with technological changes and workplace hazards.

Today, the most recent version of the standard is ANSI Z87.1-2020, which outlines requirements for the design, performance, and testing of safety glasses.

So, what does the ANSI standard require?

First, it mandates that an independent third-party laboratory must test and certify all safety glasses.

This ensures that the glasses meet minimum requirements for impact resistance, optical clarity, and protection against specific hazards.

In addition, the ANSI standard sets guidelines for the design and construction of safety glasses, including durable materials, appropriate lens thickness, and comfortable fit.

It also specifies lens performance requirements, such as minimum refractive power and resistance to fogging and scratches.

Overall, the ANSI standard for safety glasses ensures that workers and individuals are adequately protected from workplace hazards.

So if you’re in the market for safety glasses, look for ones that meet the ANSI Z87.1 standard to ensure maximum eye protection.

What are the different levels of protection that safety glasses provide?

Regarding safety glasses, it’s essential to understand the different protection levels available.

The first level of protection is impact-rated or non-impact-rated.

Impact-rated glasses provide greater protection against high-mass and high-velocity impacts.

Non-impact-rated glasses, on the other hand, are suitable for general-purpose use.

This includes laboratory work where the individual is only handling solutions unlikely to cause damage to the eye like some salts and buffers.

The second level of protection is splash and dust protection.

Safety glasses with this level can protect against droplets and splashes or dust and fine dust.

The third level of protection is optical radiation protection.

This means safety glasses can have a welding filter.

Alternatively, they can protect you from ultraviolet (UV), infrared (heat), or visible light (glare).

Understanding the different levels of protection that safety glasses provide can help you choose the appropriate level of protection for your specific needs.

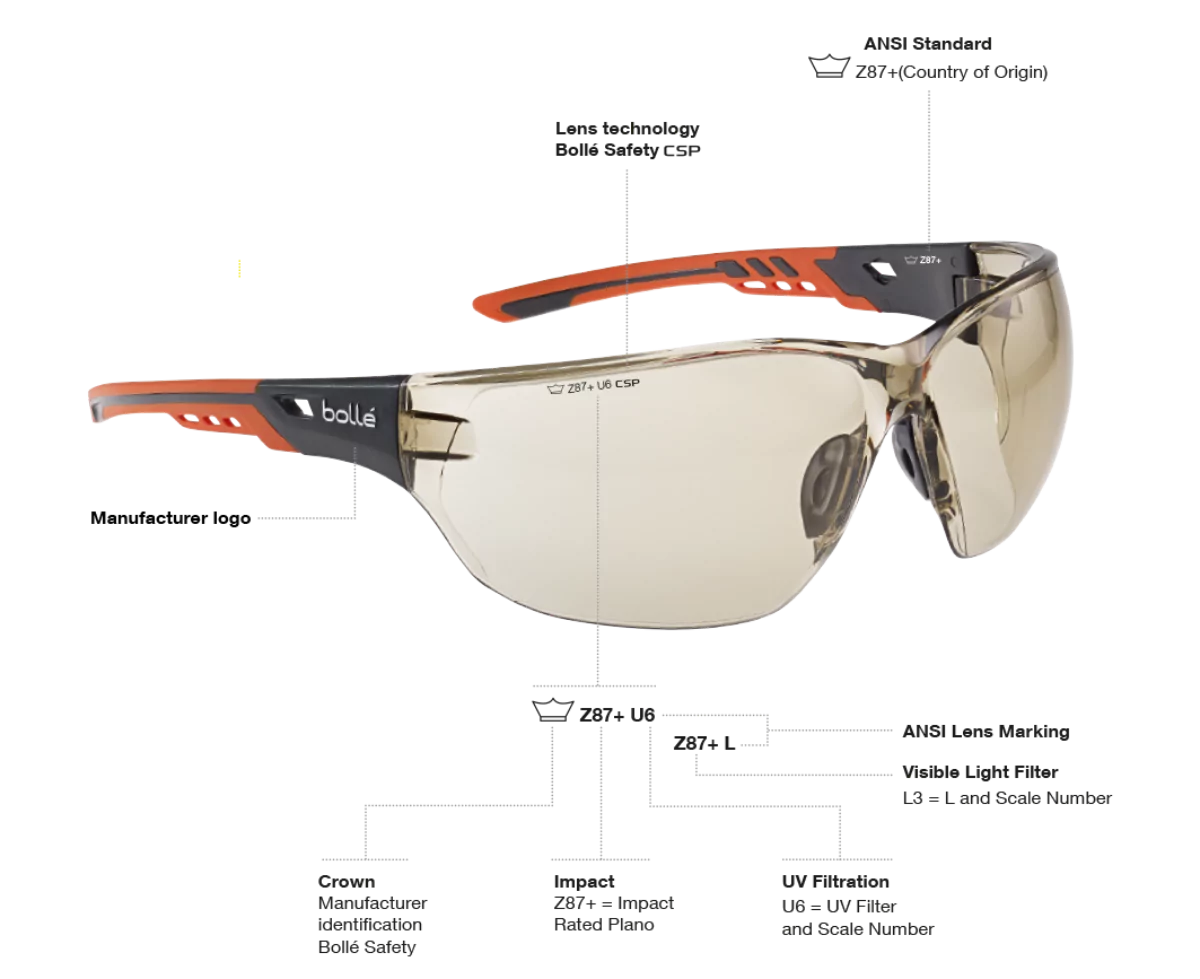

What markings do ANSI-Compliant safety glasses have?

To further understand safety glass ratings, it’s essential to look at the markings and categories associated with different types of protection.

Under ANSI Z87.1, markings are required on safety glasses to indicate their ability to protect against specific hazards.

One of the categories of markings is impact vs. non-impact.

Safety glasses that are impact-rated must pass certain high-mass and high-velocity tests and protect the sides of the eyes and face.

They’re marked with a plus symbol (+) and the label “Z87+”.

Non-impact-rated safety glasses do not have this plus symbol and are marked simply with “Z87.”

Another category is chemical splash and dust protection, which is marked with a code beginning with the letter “D.”

Eye protection glasses that meet ANSI Z87.1 requirements for droplet or dust protection are labeled “D3”, “D4”, or “D5” depending on the level of protection they provide.

D3 glasses are designed to protect against large droplets, while D4 glasses offer protection against dust particles.

D5 glasses protect against fine dust particles and are suitable for pharmaceuticals and chemical processing industries.

The last category is optical radiation protection, marked with a letter designation and a rating number.

- Welding filters are marked with a “W” and a shade number (from 1.3 to 14).

- Ultraviolet (UV) filters are marked with a “U” and a number (from 2 to 6).

- Infra-red (heat) filters are marked with an “R” and a number (from 1.3 to 10).

- Visible light (glare) filters are marked with an “L” and a number (from 1.3 to 10).

- Clear lenses have no additional marking, while variable tint lenses are marked with a “V,” and special purpose lenses are marked with an “S.”

By understanding the categories and markings associated with safety glasses, you can make an informed decision when selecting the right safety glasses for your needs.

Remember to choose safety glasses that meet the appropriate safety glass rating for your industry or activity, and consult with experts or suppliers as needed to ensure your safety.

What are some examples of ANSI-compliant safety glasses?

Here are a few examples of different brands and models of ANSI-compliant safety glasses:

1. Dewalt DPG94-1C dominator safety glasses

These glasses feature a lightweight design with a comfortable fit and rubber-tipped temples. They’re impact-resistant and have a scratch-resistant coating on the lenses.

2. 3M SecureFit safety glasses SF402AF

These glasses have a sleek and modern design with a soft nosepiece and adjustable temples for a secure fit.

They offer anti-fog and anti-scratch protection and come in various lens colors for different applications.

3. Pyramex intruder safety glasses

These glasses have a classic, simple design, lightweight frame, and scratch-resistant lenses.

They’re available in various lens colors and protect against impact and UV rays.

4. Uvex S2850 avatar adjustable safety glasses

These glasses feature a wraparound design with adjustable temples and soft nose pads for a comfortable fit.

They have a scratch-resistant coating on the lenses and offer protection against impact and UV rays as well.

ANSI-compliant safety glasses are the best choice

When it comes to protecting our eyes in hazardous work environments, safety glasses are essential.

Understanding safety glass ratings is critical in ensuring we have the right level of protection for the job.

The ANSI Z87.1 standard provides a helpful guide for evaluating and comparing safety glasses’ effectiveness.

By choosing ANSI-compliant safety glasses and understanding the different levels of protection, we can work confidently knowing that our eyes are well-protected.

Written by:

Phoebe Jade