The History of Safety Glasses & How They’ve Evolved

Imagine a world without safety glasses, where your eyes are constantly exposed to danger from all around. Luckily we don’t have to, as safety glasses have been around for a long time and have evolved along with our needs.

In this article, we’ll explore their interesting history, including how they started and innovated over the years to keep our eyes safe in different jobs and settings.

What are the origins of safety glasses?

Did you know that the history of safety glasses goes back to over a hundred years ago?

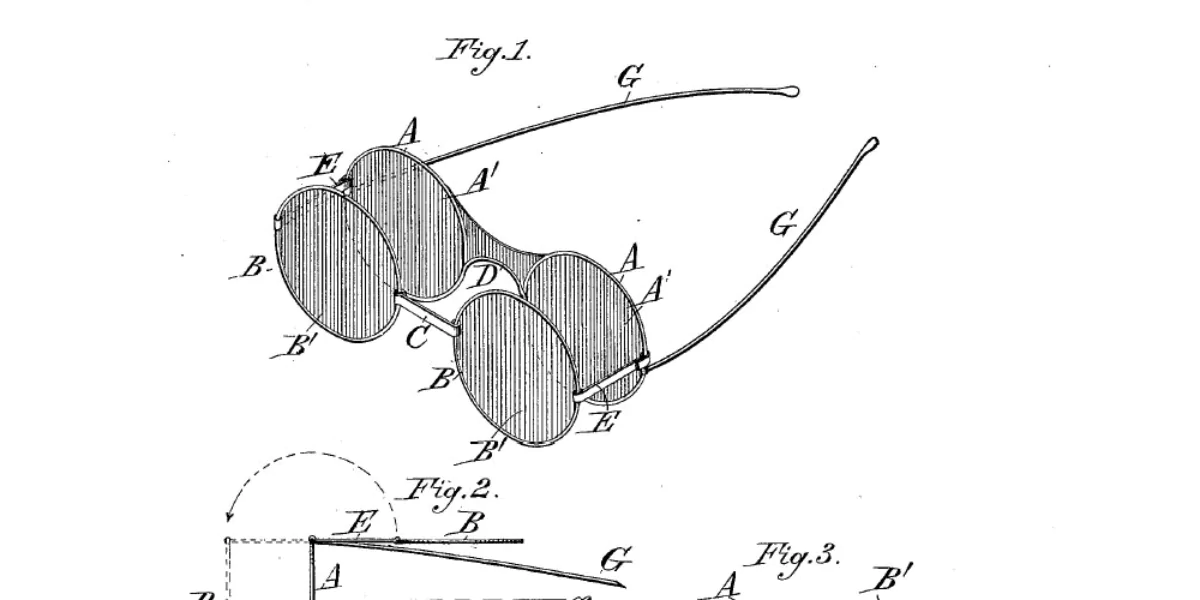

It all started in 1880 when Powell Johnson from Alabama created and filed a patent for an “eye protector.” It was made of two layers of cloth that were not completely see-through. They were intended for firefighters, furnace workers, and anyone else exposed to bright lights regularly. The purpose was to reduce the brightness and intensity of the light. These early eye protectors didn’t protect against impact or things hitting the eyes, though.

In 1903, scientist Edouard Benedictus from France accidentally dropped a glass flask and noticed it didn’t break into pieces. He discovered that the flask had a coating of liquid plastic (cellulose nitrate) inside, which kept it intact.

When he learned about a car accident where the drivers got hurt by the shattered glass windshield, Benedictus experimented with coating glass in liquid plastic. His goal was to create safety glass for car windshields and reduce the risk of injuries. Today, safety glass isn’t only used for windshields but also for safety eyewear.

In the US, Julius King, a teacher of optics, was worried about eye injuries in workplaces. Hence, his company worked with American Optical in 1909 to produce the first safety goggles called SANIGLAS. However, it wasn’t until 1914 that American Optical started raising awareness about the importance of including prescription lenses in safety goggles for workers who had trouble seeing clearly.

Furnace Goggles were created in 1935 to protect the eyes of furnace and forge workers from impact, bright light, and glare. Melter’s Goggles were also invented so steel melters could shield their eyes from flying debris, sparks, and glare.

How has the design of safety glasses evolved?

Up until 1979, safety eyewear had to meet specific shape requirements. However, the American National Standards Institute (ANSI)’s standards were revised in 1979. Now, different designs are allowed as long as the glasses pass specific high-impact and high-speed tests. This gave room for more stylish and lighter safety glasses to be made.

In the past, safety glasses lenses were made of glass and hard resin, which were fragile and could cause additional harm. Then, polycarbonate became available in the 1970s. Known for its strong impact resistance, polycarbonate was then introduced in protective eyewear lenses made by Gentex Corporation in the 1980s. They were the most lightweight and thinnest lenses at the time. To make safety glasses more durable, hard coatings were eventually added to help protect lenses against scratches and chemicals.

Anti-fog technology was invented by NASA to solve the problem of fogging visors in space. In 1966, astronaut Eugene A. Cernan developed and tested an anti-fog solution during a spacewalk. It proved to be effective and convenient. Since then, anti-fog technology has evolved and is now available in various forms, like wipes, gels, sprays, and coatings that can be added to safety lenses.

What about safety glasses today?

Modern safety glasses offer a host of enhanced features for better vision and comfort. For starters, they have polarized and tinted lenses to reduce reflections and glare, photochromic lenses that adjust to sunlight, and built-in magnification for reading or close-up work.

Prescription inserts are also available for those who prefer not to wear glasses or contacts.

They’re available as single-vision, bifocal, or progressive lenses. Single-vision glasses have one lens prescription strength. Bifocals have two with a line in the middle, while progressives have three without a line in between. These glasses make it easier to see clearly and work safely.

Safety glasses can also have built-in reading lenses to help with close-up tasks. They provide magnification for reading and detailed work, so workers can switch tasks without needing separate glasses. This innovation improves convenience, comfort, and safety in different work environments.

Besides that, manufacturers have made safety glasses more comfortable by adding expandable side arms, adjustable nose pieces, padding for the nose and ears, and made them more lightweight.

What’s more, there are lens coatings like anti-reflective and scratch-resistant coatings. Anti-reflective coatings reduce glare and improve clarity. Scratch-resistant coatings protect lenses from scratches and increase durability. These advancements improve the performance and lifespan of safety glasses.

Safety glasses of the future

In the coming years, safety glasses are expected to have augmented reality (AR) technology.

AR will show real-time information and visuals in the wearer’s view. It can improve awareness and decision-making, as well as allow hands-free operation. Additionally, they may have digital overlays, facial recognition, and communication features. That means AR in safety glasses can further improve the way we work and help us stay safe.

Sensor technology is also expected to be used in safety glasses to improve workplace safety. Sensors in the glasses will detect hazards like gas leaks and high heat. They can also monitor the wearer’s vital signs, like heart rate and body temperature. This helps prevent accidents and enables the wearer to quickly respond to changing conditions.

Furthermore, manufacturers are also working on improving the comfort of safety glasses. One area of improvement will be in the way colors and contrasts are seen. Manufacturers are looking to develop glasses with more options for lens colors that cater to the needs of different workplaces. These glasses will help the wearer see better, feel more comfortable, and work more efficiently and safely.

Additionally, safety glasses are getting easier to use and more are being designed for specific industries. People in sectors like manufacturing, security, healthcare, and cleanrooms (controlled environments with strict rules to prevent contamination) can find glasses made just for them.

Safety glasses: Enhancing workplace safety and beyond

Safety glasses have come a long way, from the simple eye protector to the modern version we know today with all the safety features and bells and whistles. These days, it’s easier than ever to find specialized designs for different industries, and they cater to more people with different refractive errors too.

If you’ve enjoyed today’s historical deep dive, be sure to check out our other piece on the evolution of eyeglasses too. There’s always more to discover on Mouqy’s blog!

Written by:

Phoebe Jade